Since 1999

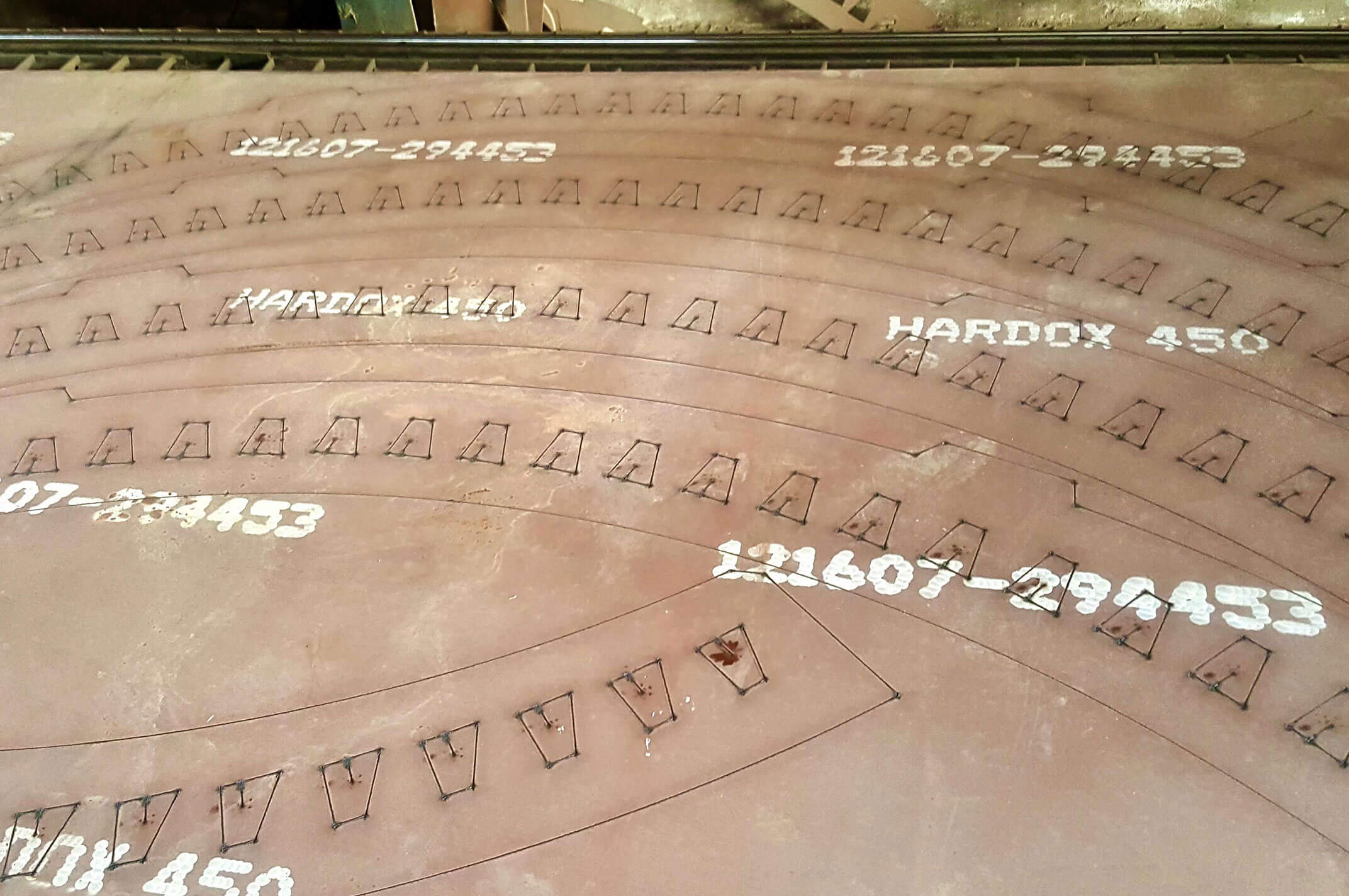

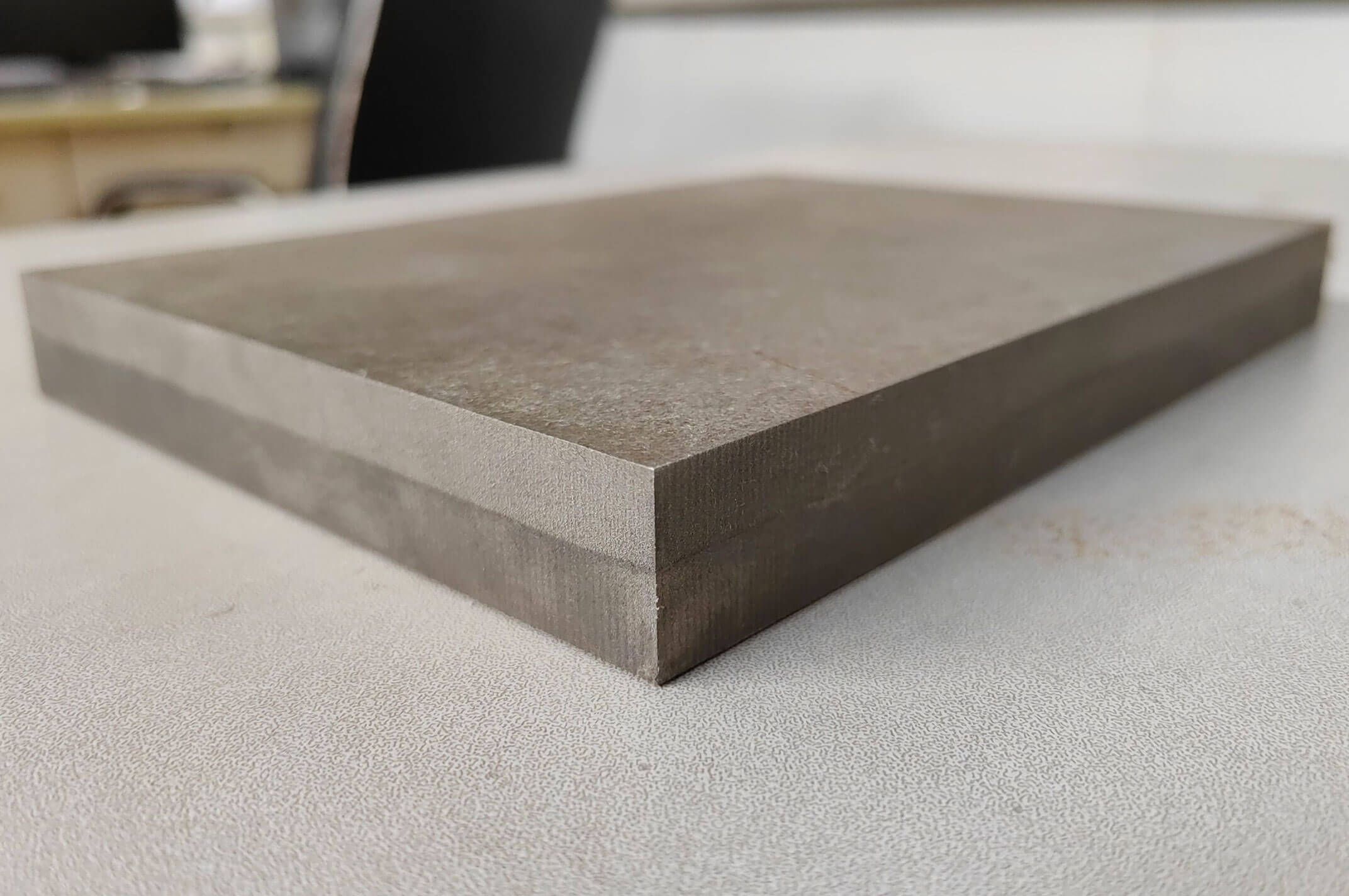

Durametal has specialized in custom manufacturing industrial spare parts and ready-made anti-wear products. We provide tailored solutions based on client-supplied drawings and/or samples.

Your Source for all your spare parts

Our process

Annealing

Used to reduce hardness and enhance ductility of metal components.

Carburizing

Ideal for enhancing surface hardness while maintaining a tough core.

Quenching & Tempering

Strengthen metal parts by controlling the cooling process.

Hardening

Ideal for components requiring superior hardness and wear resistance

Stress Relieving

Eliminates internal stresses caused by welding or casting

Ask Us a Question…

The point of using Lorem Ipsum is that it has more-or-less normal

General Questions

01. Why is sand important for industry?

Randomised words which don’t look even slightly believable. If you are going to use a passage of Lorem Ipsum, you need to be sure there isn’t anything.

02. Can I switch to a different plan?

Randomised words which don’t look even slightly believable. If you are going to use a passage of Lorem Ipsum, you need to be sure there isn’t anything.

03. What should I wear for an industry treatment?

Randomised words which don’t look even slightly believable. If you are going to use a passage of Lorem Ipsum, you need to be sure there isn’t anything.

04. Can you give tips for the stock market?

Randomised words which don’t look even slightly believable. If you are going to use a passage of Lorem Ipsum, you need to be sure there isn’t anything.